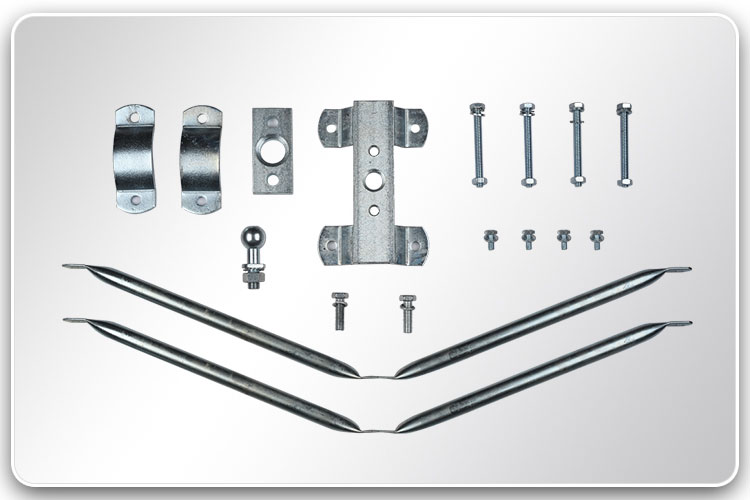

Mirror Bracket

Mirror Bracket, also called mirror holder, is a series of products that we developed for a client from Scandinavia. Mirror Bracket products are used for holding mirrors for following applications:-Traffic mirrors-Cashier and observation mirrors-Mounting material and fixing brackets-Inspection mirror......

Send Inquiry

Product Description

Mirror Bracket, also called mirror holder, is a series of products that we developed for a client from Scandinavia. Mirror Bracket products are used for holding mirrors for following applications:

-Traffic mirrors

-Cashier and observation mirrors

-Mounting material and fixing brackets

-Inspection mirrors

-Industrial mirrors

The process of Mirror Bracket manufacturing generally includes 4 steps - cutting, forming, assembling, and surface treatment.

-Cutting Process

We offer various cutting options including oxygen cutting, laser cutting, plasma cutting. For these mirror bracket products, the stamping is the most common way for material blanking.

-Forming Process

The forming process typically includes bending, punching, and milling. The nature of the parts’ design determines the method used. Deburring is an essential procedure before welding and assembling.

-Assembling

For mirror bracket products, one of the critical process of assembling is welding. Fixtures need to be pre-designed and made to ensure a product with no distortion after welding. Some areas require milling after assembling. A set of test gauges are pre-developed for quality inspection, ensuring the complete functionality of the product.

-Surface Treatment

The normal surface treatment processes of mirror bracket product is blue zinc plating, other surface treatment including electrophoresis (KTL), powder coating, painting, hot dip galvanization are also available. For all surface treatment quality control, we offer coating adhesion, thickness, and salt fog tests or, other tests to be conducted upon request. Anodizing is available with aluminum materials.